Silicone Implant Manufacturers

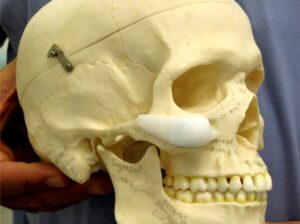

Custom silicone implants are available in various sizes and shapes. The implants are made of silicone, a natural substance that is common in the earth’s crust. When silicon is combined with oxygen, carbon, and hydrogen, it is formed into silicone. A variety of different forms of silicone are available for manufacturing. They can be found as oils, gels, or solids. The material used in these custom implants is composed of silicone. Several different implant manufacturers are available for custom needs.

custom silicone manufacturers implants are available in a variety of shapes and surfaces. The most common type is smooth. This is made by repeatedly dipping a mandrel in silicone and letting it cure in a laminar flow oven. Alternatively, a textured implant may be manufactured using a more intricate method. Salt-loss technique is used to create a textured implant. The dipped silicone mandrel is then washed to remove the salt crystals. Another technique, Siltex, is created by negative contact imprinting, where the dipped mandrel is placed into a foam of PU. The pore size is intended to mimic that of the PU foam.

The underlying materials used for custom silicone implants can vary greatly. Generally, silicone implants are manufactured by repeatedly dipping mandrels in silicone. They are then cured in a laminar flow oven. However, if textured implants are desired, an intermediate step must be performed so that the material can be texturized. The Biocell surface is produced using salt-loss technique, where salt crystals are added to the dipped mandrel before curing. The crystals wash away leaving a pitted surface. In contrast, the Siltex surface is created through a negative contact imprinting technique, in which the dipped silicone mandrel is pressed into PU foam. The resultant pore size mimics that of the PU foam.

Custom Silicone Implant Manufacturers

Silicone implants are available in many different styles and materials. The most common types are round and textured. The smoothest implant is manufactured by repeatedly dipping the mandrels in silicone. The textured device has a higher cost and is less efficient. It is important to choose a custom silicone implant manufacturer that has the right equipment and experience to produce a customized implant. Once a custom implant is made, it will be customized to suit the patient’s needs and preferences.

There are a number of factors that determine the quality of custom implants. The design, material, and shape are just a few of the factors to consider. The quality of the implant will determine how well it fits the patient. This is the reason for customization. Once the device is made by a custom manufacturer, the quality is better, and it will look more natural. In fact, the procedure will last a longer time if it is done correctly.